Traditional air springs fill compressed air into a sealed container, typically made of rubber, to form an airbag with ideal elastic properties. Based on the working principle of rubber airbag structure, the company's technology research and development department has developed a rigid cylinder block as an energy storage chamber for compressed air. Compressed air is used instead of mechanical springs to output displacement and force, and an air powered actuator has been invented, which has been successfully applied in valve regulation and switch control.

● Use air springs instead of traditional mechanical springs.

● The preloading of the air spring can be adjusted arbitrarily.

● Air compression directly affects the piston area, resulting in high output force and mechanical efficiency.

● The positive and negative effects do not require replacing the actuator, only changing the intake method.

● The air spring has no mechanical fatigue.

● It is allowed to use a gas source pressure of up to 0.7MPa.

● For the same model, there are different output forces based on the preloading size, and different input gas source pressures can be selected to save energy and reduce consumption.

● Small size and lightweight aluminum alloy cylinder.

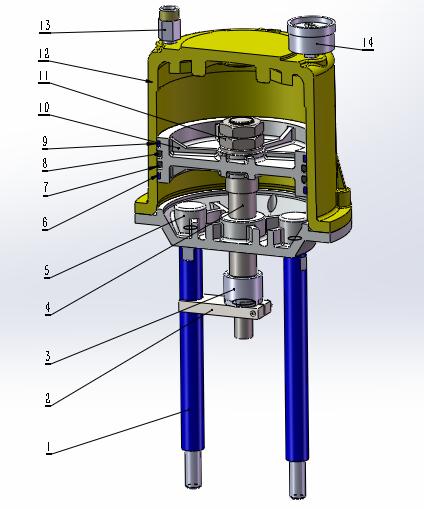

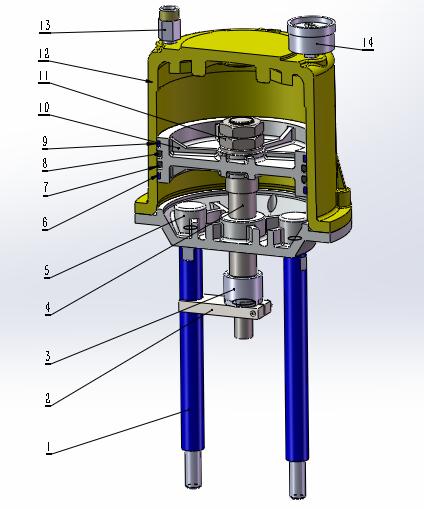

Product structure: Technical principle:

Technical principle:The air spring cylinder is a new type of pneumatic actuator developed by our company. This product holds multiple utility model and invention patents. Its structure and principle are shown in the following figure.

Principle: Pre-compressed air is introduced into the air chamber A of the cylinder and locked by the check valve, thus forming an air chamber with compressed air as energy, which acts on the piston area to generate output force. The size of the pre-compressed air in the air chamber A can be freely set according to the valve parameters.

When the gas source enters gas chamber B through the positioner, as the control signal (4-20mA) increases, the piston begins to move upward, and the space of gas chamber A shrinks until the pressures in gas chambers A and B are equal. When the positioner signal decreases, the prepressure in the A air chamber pushes the piston to move downward.

The pressure in the A air chamber is equivalent to air replacing the spring to store energy, forming an air spring, and the pressure reducing valve (2)

Set A constant value for the pressure in Chamber A, and provide immediate replenishment when the pressure in Chamber A drops below the constant value. Ensure that the pressure in Chamber A is a constant value. To meet the initial preload for forming the air spring. Its advantage is that this preload can be freely set according to the size of the pressure difference overcome.

When it is necessary to change the mode of action, only the B air chamber needs to be used as the constant air chamber and the A air chamber as the air source for air intake. Operationally, simply change the air intake interface to achieve quick interchange between the forward and reverse effects.

Key technologies● The cylinder is made of low-pressure cast aluminum alloy and undergoes solid solution and aging (T6) reinforcement treatment. The entire cylinder is small in size and light in weight.

● The guide ring is made of low-friction, long-life and wear-resistant materials, and the guide is widened to avoid direct friction between metals.

● The sealing ring adopts a combined sealing structure, which can ensure low friction. It uses a patented grease storage sealing structure to form multiple seals, ensuring zero leakage during long-term use.

● The inner wall of the cylinder is hardened and processed by high-precision CNC machine tools to enhance its smoothness and wear resistance.

● The surface of the cylinder is treated with plasma spraying process, which effectively prevents corrosion.

Compared with traditional executive agencies

● It can replace traditional single-spring and multi-spring actuators.

● Greater output force and simpler structure.

● Make full use of aerodynamics to save energy and reduce consumption

● Light in weight, the aluminum alloy anodized passivation has excellent anti-corrosion ability.

● There is no fatigue phenomenon of mechanical springs, which increases the service life.

● Advanced wear-resistant and sealing technology, reliable quality.

● Structural dimensions and output thrust

Chemicals, Electric Power, Food Processing, Paper Manufacturing, Textiles, Pharmaceuticals, Steel, Water Treatment.